Our Value

-

3

Generations

-

35

Professionals

-

22mila

m² of production plant

-

100

m³ of wood processed per day

-

60

m³ of finished product per day

-

Local Roots

We have always been a family first and foremost! Over the years, we have grown from 12 to 45 people, but we remain a close-knit team in which everyone takes care of their neighbour in the supply chain and ensures that the final result maintains the high quality of our craftsman tradition.

From grandfather Antonio Giacomuzzi, to his 3 children, to our first 12 specialized partners, to today's great team.

-

A Global Spirit

The pandemic did not stop us! On the contrary, it gave new energy to our desire to do and grow, so much so that, in recent years, we have bravely made the definitive leap towards industrial dimensions with new people, new equipment, and a new 32,000-m2 facility. More work and more of a future for us and our valley.

Two facilities with a combined areaof 42,000 m2 between Ziano in Trentino and San Lugano in Alto Adige.

-

A Natural Evolution

Our sector was traditionally ”male” until a few years ago. We have the mobility crisis created by the pandemic to thank for finally starting to receive job applications from women as well. Today, our team is more complete, and we are happier for it.

A close-knit team of over 40 professionals, including employees, agents and collaborators.

-

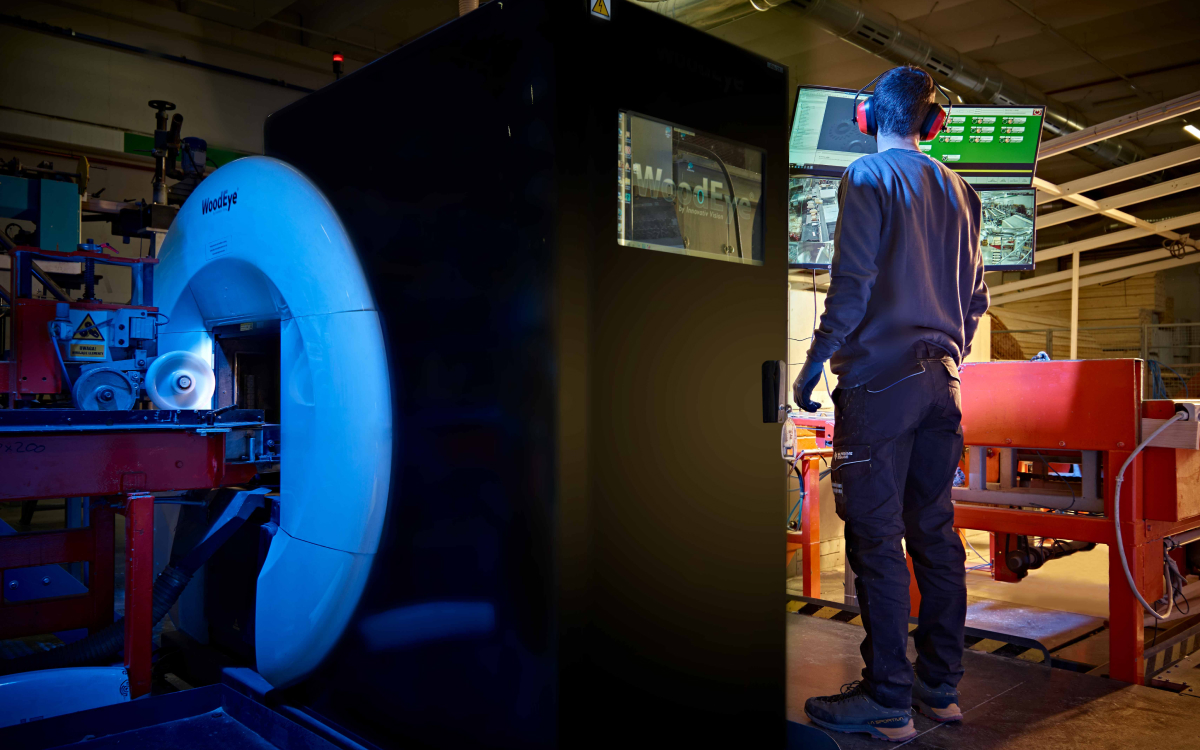

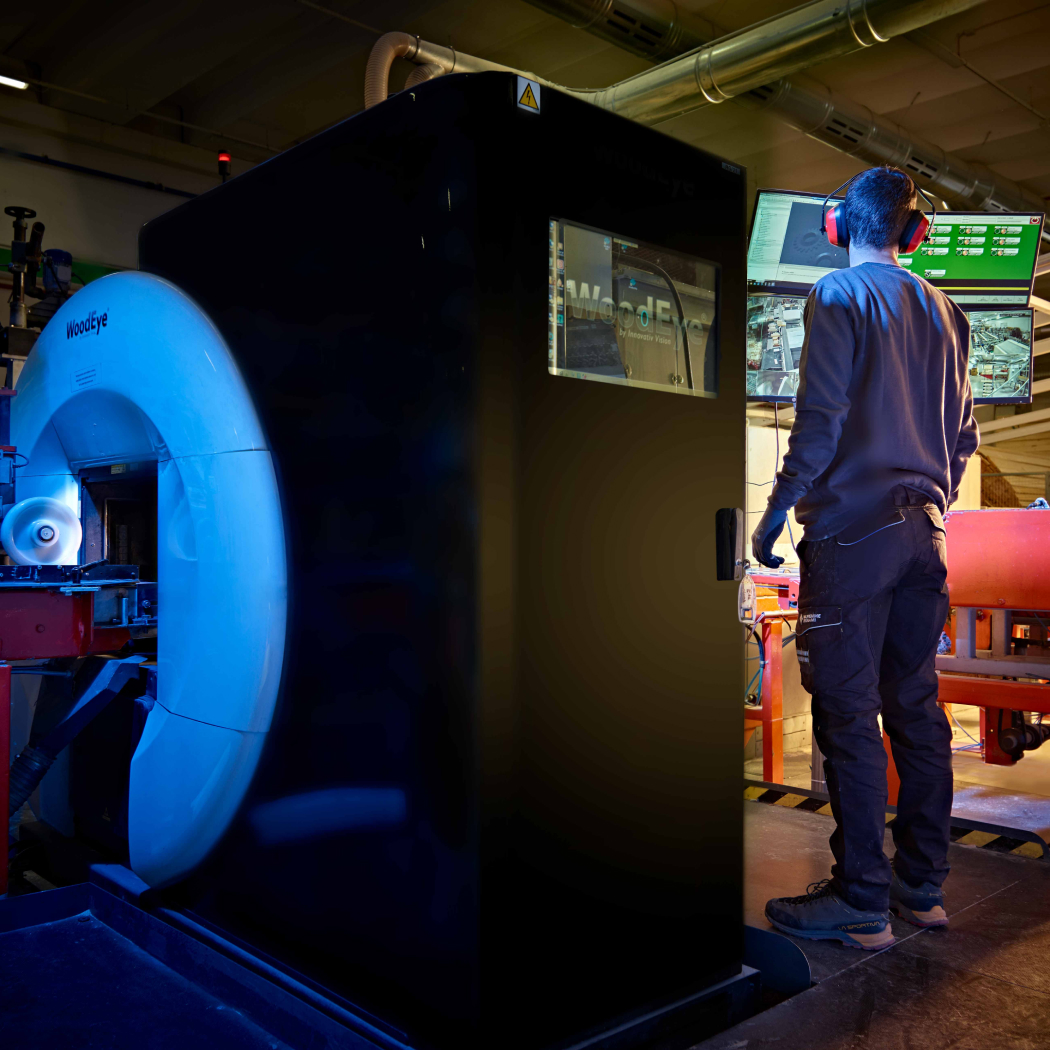

Technological Well-being

We work with the latest technology available in our sector to guarantee speed, precision, and a superior finished product. This applies to the production lines as well as to the safety systems to fully protect the well-being of all employees.

data on equipment/technology/safety

-

Logistic Efficiency

We take care of the logistics directly, using our own fleet managed very well by our team of hauliers. We always try to optimise loads to minimise environmental impact.

Our 2 trucks and our tractor are driven by our hauliers.

-

Sustainable Thinking

We spend a lot of time thinking about how to minimise our impact on the environment. It’s in our nature! We only use wood from responsibly managed, PEFC certified forests. To cover our power needs, we have a fully-operational solar plant on the roof of our facility. In our processes, there is no raw material waste because the scraps are made into sawdust for pellets or animal hygiene products and wood chips for producing thermal energy. We always do our best to load our transport vehicles to capacity for fewer trips and to lower our impact.

PEFC certified material, energy independence, and zero waste for a green future.